FEDERAL HILL TRADING COMPANY

OEM suppliers since 1995 in small bore hydraulic tubing for automotive and light truck brake applications.

-

OUR PHILOSOPHY

"Lasting value is built with quality products and expertise."

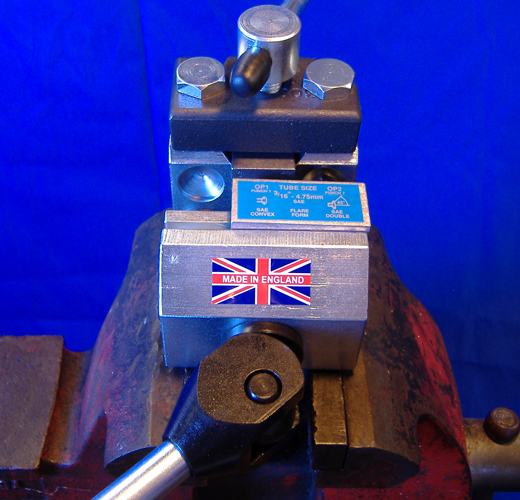

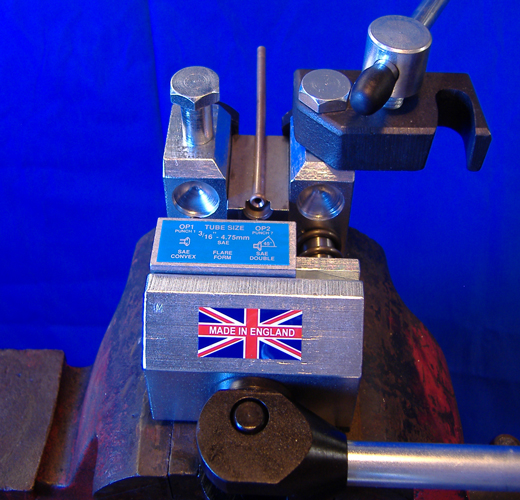

007 brake line flaring tool instructions

Touch pictures to enlarge.

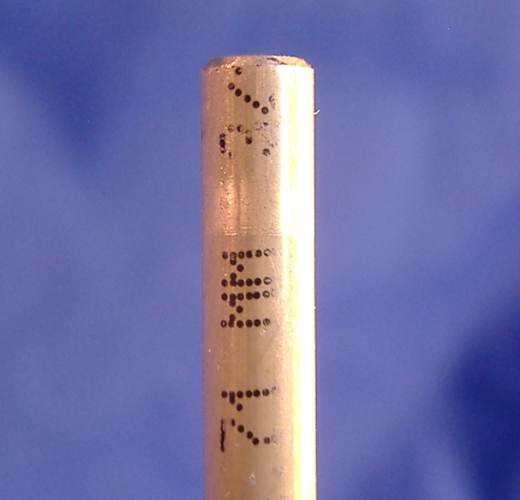

Step 1

Before cutting the tube make sure that it is perfectly straight where you are going to cut it. Cut the tube with a tubing cutter or fine tooth hacksaw. Prepare the end of the tube with a fine tooth flat file. First, file the end of the tube flat and square. Then deburr the inside of the tubing. Finally, file the outside corner of the tube at a 45 degree angle. Do not file to a sharp edge at the ID. If needed flatten the end again with the file.

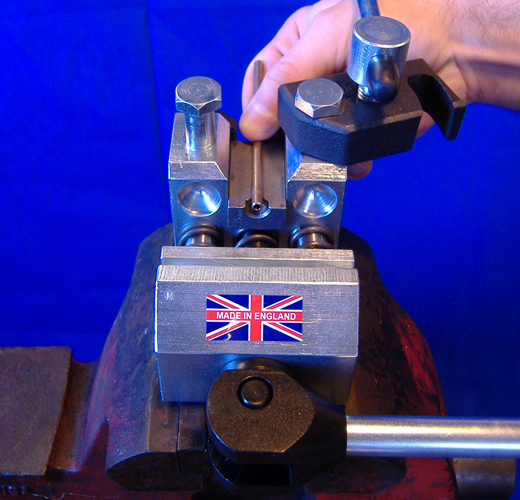

Step 2

Place the correct die block for the tubing being used as shown into the tool. Make sure the forming die end of block is facing the punch. Place the correct nut (pointing the right way) on the prepared tubing. Place the tubing into the die block even with the end of the die block.

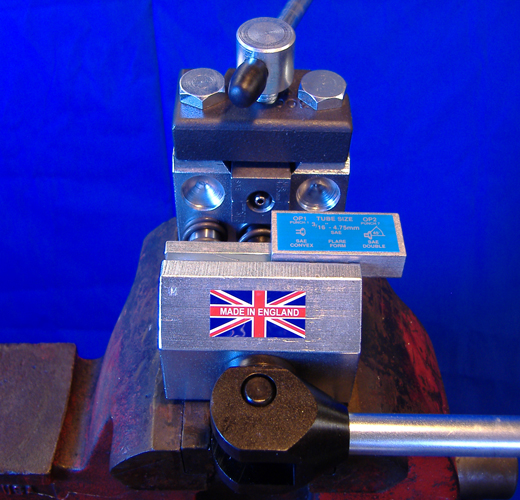

Step 3

Place the other half of the die block on top of the first, again making sure the forming end is facing out. Slide the die blocks to the rear stops and make sure the tubing is flush with the end of the die blocks. Swing gate closed and tighten by hand.

Step 4

Make sure you have the matching punches for the die blocks being used. Position the OP1 punch (operation 1) in line with the end of the tubing. Hold the punch while operating lever to pilot the punch into the tubing.

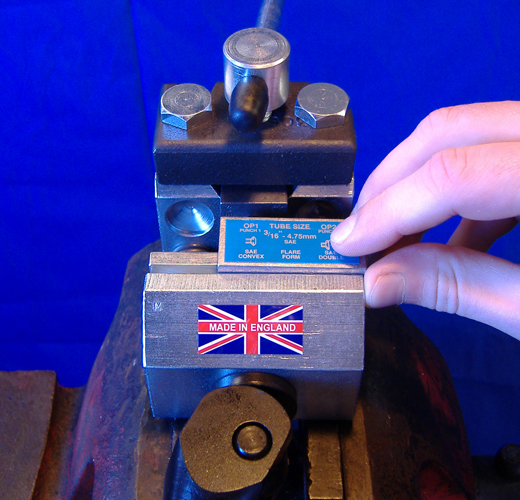

Step 5

Once punch is positioned push lever firmly by hand only. No need to push extremely hard. If it does not want to flare readily make sure you don't have one of the die blocks in backwards. This is all that is required to make a DIN (ISO/bubble) flare. Repeat this procedure with the OP2 (operation 2) punch to complete the SAE (double/inverted/45 degree flare).

Step 6

Open the gate, remove the tubing from the die blocks, and inspect. Practice making flares with too much tubing sticking out and too little to see what happens. If you have too much sticking out or you over press a DIN flare the punch may stick in the die block. Simply pop the punch and jaw assembly loose by using a large screwdriver or wrench to lever it open.

Hover over picture to enlarge.

/